Traditional paints and coatings applied to corrosion give disappointingly short-lived performance because they simply hide the underlying and continuing corrosion – the failure is first seen by blistering of the coating and the rapid breakthrough of rust.

Hydrate-80 provides powerful protection to rusted steel surfaces, its electrochemical function stabilises existing corrosion by converting the iron oxides into a protective metal complex and it also combines with surface moisture and oxygen depriving the corrosion process of the conditions it requires. Paints and coatings applied to a Hydrate-80 treated surface demonstrate amazing improvements in long-term performance.

Hydrate-80 provides a superior stable barrier to prevent further attack. The cross-linking polymer formulated to provide the tough non-rubbery barrier tenaciously grips the metal surface forming an ideal base for further coatings, paints or anticorrosion wax.

Importantly for long-term protection Hydrate-80 doesn’t contain chlorine which is known to transform into corrosive hydrochloric acid in rust converter applications causing under-film blistering and destruction of paint finishes or other coating products.

Quick Guide

- Proven long-term rust prevention over partially prepared surfaces – massively increases the life of paint applied to partially cleaned steel.

- Boosts the corrosion protection of coatings applied to steel that has been cleaned by blast cleaning or other methods.

- Easy-to-use simply brush or spray apply.

- Safe, water-based and non-flammable.

- Leaves surface ready for painting.

- Produces super-tough non-rubbery etched barrier.

- Surfaces do not need washing after treatment.

- Low viscosity wets out corrosion for full conversion and facilitates penetration of flanges and seams.

- Proven in independent TÜV tests in trials of automotive paintwork.

- Awarded “Product Recommended” in Practical Classics magazine long term trial.

Long Term Performance

The long-term performance of Hydrate-80 has been proven to significantly increase coating life in independent tests conducted by the German TÜV organisation under conditions of VDA 621-415 (6 cycles, or 1008 hrs) which included exposure to hot salt-spray, 100% relative humidity and drying atmospheres with each cycle lasting 168 hours.

Hydrate-80 was awarded Practical Classics magazine "Best Buy” and “Product Recommended” after a long-term trial comparing it to 12 other products – in fact Hydrate-80 was applied to more heavily corroded steel than the competition and still outperformed them. Hydrate-80 has been used to arrest and prevent corrosion in diverse applications – from massive marine installations to classic and historic vehicle restoration Hydrate-80 provides dependable long-term protection.

How to use Bilt Hamber Hydrate-80

As with all treatments preparation is important:

Remove loose, flaky rust with a wire brush and abrasive paper (or if favoured power tools). The active ingredients of Hydrate-80 must reach the oxidising surface of the steel. Thoroughly degrease the area and wash well with clean water to remove dust and contaminates. Failure to degrease area properly will cause “holidays” or fish-eye like flaws in the barrier.

Shake vigorously and pour sufficient quantity into a non-metallic container, do not return unused product to the original container, contamination transferred in this way will activate the product.

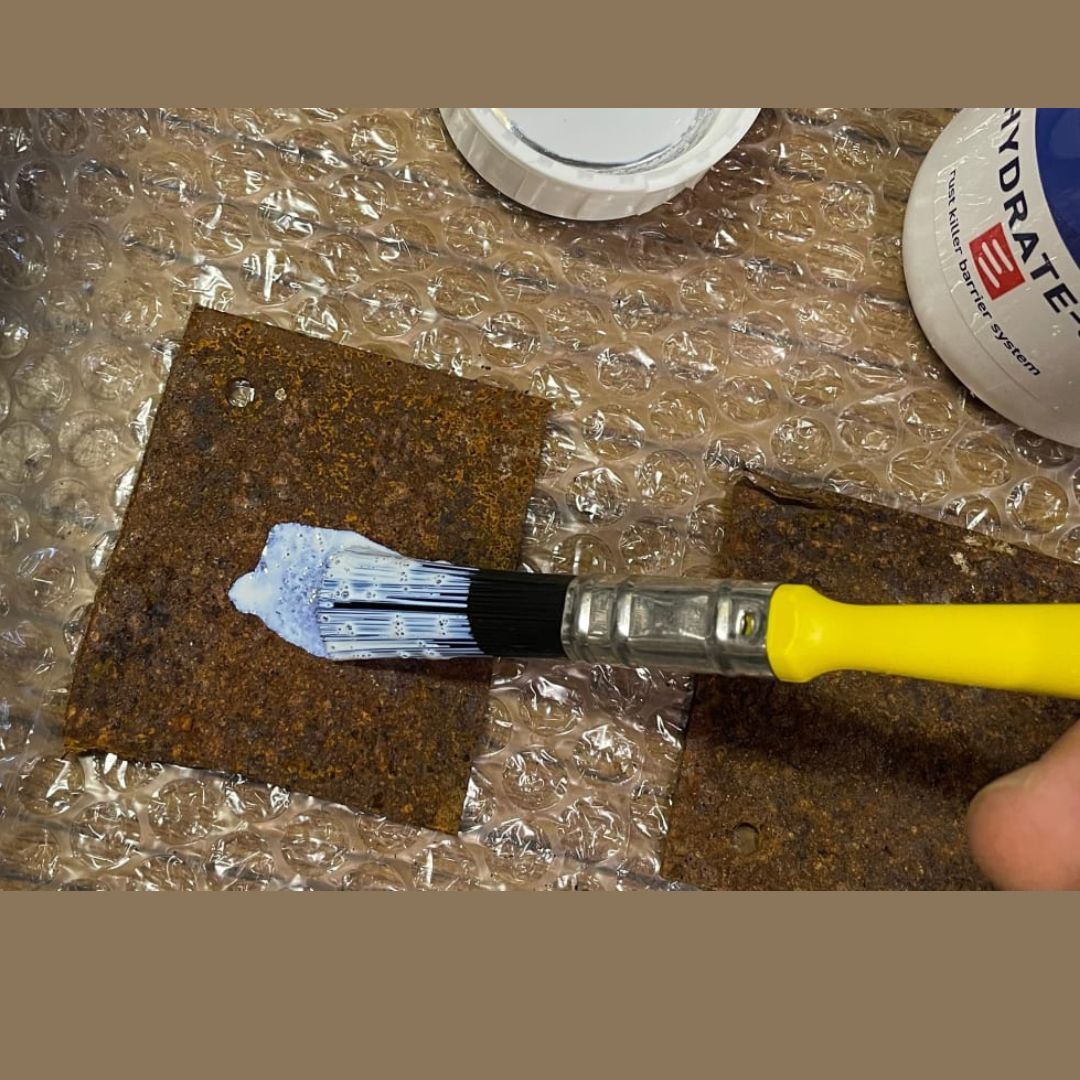

Apply sparingly, two coats at 30 minutes interval. The first coat should be worked into pitted areas and then smoothed by brush strokes in one direction. Excess application should be avoided. The second coat should be applied at a 90 degree angle to the first. For best results leave for 24 hours after which finishing coats may be applied.

Where rapid work progress is required Hydrate-80 can usually be over coated after three hours without performance loss. Hydrate-80 can be brush or spray applied – though brush application is preferred. Spray application should be made by first applying a light mist coat which is left to tack dry (5-10mins) then apply full coat not to excess. Flatting back of coats is possible using dry wet or dry paper; care should be taken not to abrade through the barrier. Use of Hydrate-80 below 10 degrees C will result in slow reaction time and barrier formation.

As Hydrate-80 will activate on clean steel the affected area should be cleaned beyond the visibly corroded surface, this will ensure complete treatment. Wash equipment with water. Wash hands with soap and water after contact and in case of contact with eyes wash with plenty of running water and seek medical attention.

Hydrate-80 is an excellent base for a wide range of paint finishing systems. It is preferable, but not essential to use a good quality primer before applying topcoats.

Due to the many types of paint formulations and curing processes test compatibility of products at small scale before use.